Factory source Electric Weaving Loom - YTB 6/55 high speed needle loom – Yitai

Factory source Electric Weaving Loom - YTB 6/55 high speed needle loom – Yitai Detail:

Application:

The machine is suitable to produce different types elastic and elastic products such as shoelace, elastic belt, decorative belt, high tension belt, sports belt, curtain belt, medial bandage, sofa tape, mattress tape, medal tape, bag belt, pet leash, ribbons, lifting tapes, twill tape, seatbelt, luggage strap etc.

Yitai YTB high speed narrow fabric needle loom machine features:

This machine has 2 to 16 lines, width can produce from 2mm to 150mm by different models. Machine working width has various typee to meet different factory’s capacity required. With auto-lubrication system and yarn auto-stop motion system to improve product quality, save working time.

Imported bearings such as NSK, NTN, FAG etc. to ensure quality.

The wide range adopts double shedding lever and double chain like to transmit, which strengthen the axis and transmission structure of gears, we are the first one to produce such wide machines in China mainland.

Reasonable back creel design for easy assembling and adaption.

Back take-off device and beam creel are changeable according to buyers’ required.

Spare parts requirements:

Please fill out the form by “ spare parts inquiry” if you have any spare parts requirement, and provide nameplate of the machine. Send drawing according to the spare parts manual, real spare parts need be provided if necessary.

Standard equipment:Back creel

Optional attachment:

● Back take-off device

● Front take-off device

● Rubber feeder

● Rubber roller

● Double weft double latch needle

● Double weft single latch needle

● Extra long chain

● Warp feeder – belt type

● Double-decker device

● Double weft and double latch needle for curtain tape device

| YTB 430,560 & 610 Series Specification | ||||||||

| Model | 2/110 | 2/150 | 4/65 | 6/55 | 8/30 | 10/25 | 12/20 | 4/80 |

| Tapes | 2 | 2 | 4 | 6 | 8 | 10 | 12 | 4 |

| Reed width (mm) | 110 | 150 | 65 | 55 | 30 | 25 | 20 | 80 |

| Motor | 1.5HP | |||||||

| Speed | 1200-1400 RPM | |||||||

| Heald frame | 12-16 pieces | |||||||

| Design chain circle | 8-48 | |||||||

| Weft density | 3.5-36.7 WEFT/CM | |||||||

| Normal attachment | 8-21 yarn creel places | |||||||

| 0ptional attachment | Beam,rubber feeder,back take-off device,double hook single needle system,cree l | |||||||

| YTB 860 Series Specification | ||||||||

| Model | 4/110 | 8/55 | 6/80 | 10/45 | 12/30 | 14/25 | 16/20 | 8/60 |

| Tapes | 4 | 8 | 6 | 10 | 12 | 14 | 16 | 8 |

| Reed width (mm) | 110 | 55 | 80 | 45 | 30 | 25 | 20 | 60 |

| Motor | 2HP | |||||||

| Speed | 1000-1200 RPM | |||||||

| Heald frame | 12-16 pieces | |||||||

| Design chain circle | 8-48 | |||||||

| Weft density | 3.5-36.7 WEFT/CM | |||||||

| Normal attachment | 16-21 yarn creel places | |||||||

| 0ptional attachment | Beam,Rubber feeder,Back tape-off device,Double hook single needle system, creel | |||||||

| YTB-D Series Specification | ||||||

| Model | 8/30 | 10/25 | 12/20 | 14/20 | 12/30 | |

| Tapes | 8*2 | 10*2 | 12*2 | 14*2 | 12*2 | |

| Reed width (mm) | 25 | 20 | 15 | 15 | 25 | |

| Motor | 1.5HP | |||||

| Speed | 1200-1400 RPM | |||||

| Heald frame | 12-16 pieces | |||||

| Design chain circle | 8-48 | |||||

| Weft density | 3.5-36.7 WEFT/CM | |||||

| Normal attachment | 16-21 Creel places,Normal attachment | |||||

| 0ptional attachment | Beam,Rubber feeder,Back tape-off device,Creel places | |||||

Product detail pictures:

Related Product Guide:

We usually perform being a tangible workforce making sure that we will give you the most beneficial excellent plus the finest selling price for Factory source Electric Weaving Loom - YTB 6/55 high speed needle loom – Yitai , The product will supply to all over the world, such as: Mongolia , Los Angeles , Latvia , We adhere to client 1st, top quality 1st, continuous improvement, mutual advantage and win-win principles. When cooperation together with the customer, we provide shoppers with the highest high-quality of service. Established good business relations using the Zimbabwe buyer inside the business, we've got established own brand and reputation. At the identical time, wholeheartedly welcome new and old prospects to our company to go to and negotiate small business.

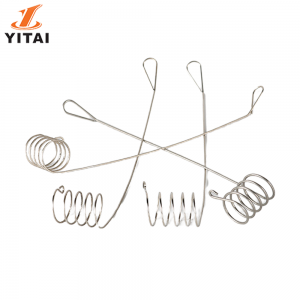

Parts list (More other spare parts available. Please contact us to get more spare parts details.)

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!